No picture? ![]()

Ideal for Joe Bonamassa or Samantha Fish… ![]()

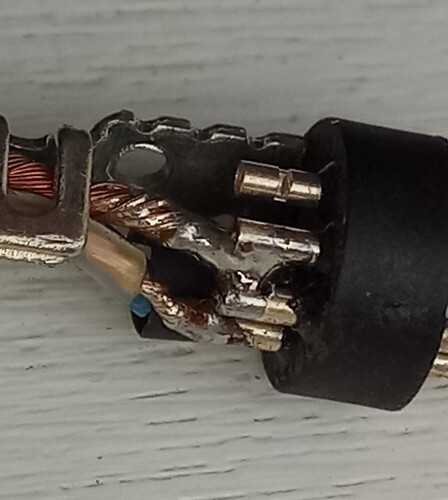

(the DIN plug used is very old… I bought it when I was still at school…!!)

If you’re using 4 core and have to combine 2 cores which are connected to ground, soldering to a single din pin is difficult.

The solution is to solder to the ground pin and the unused pin next to it.

As precaution, it’s a good idea to remove the unused pin. ![]()

Yes, I was going to add, in my previous post, that a programmable soldering station would also be a very good idea.

I wasnt sure if it was moving outside of the scope of the conversation…

i.e someone just wanting to “have a go”.

These can be had at very reasonable cost for the hobbyist.

Very often any poor quality solder joints obtained by a newcomer are down to the lack of temperature control on the soldering irons side, or cheap ineffective solder - not because soldering is terribly difficult!

Usually, a cheap soldering iron - “metal stick, with plastic handle, on the end of a plug chord, for £5” type of thing will be unable to maintain a regulated temperature, even more so on jobs like Naim speaker plugs where there is enough mass to dissipate the heat immediately it’s applied.

By the time sufficient heat is finally attained at the solder site, the entire device being soldered has reached melting point!

The idea of a temperature controlled iron is to sense and adjust/compensate the heat at the irons tip continuously and very quickly, permanently maintaining the correct set temperature rather than allowing the heat to be quickly dissipated, leaving the tip ineffective.

A good quality leaded solder, containing proper amount of flux, is prefferable, imho.

Pretty much any brand name solder from a reputable electronics supply company will work fine.

Multicore is a good brand, imo. Now owned by, and possibly branded as, Loctite. But I’m sure everyone has their own preference !

Here in the UK the RoHS only pertains to businesses/manufacturing - not to home hobbyists as far as I was last aware (although maybe others kmow differently?) so unleaded solder is not a legal requirement for hobbyists in the UK, as some believe.

Personally I much prefer leaded, although as usual others preferences will differ!

I take into account that most companies only changed to lead free when they were forced to. Not many seemed to have chosen to switch to lead free before the RoHS compliance became necessary.

A fan based fume extractor is a very good idea.

The fumes (predominantly caused by the rosin in the flux - not lead!) are pretty unhealthy.

An illuminated magnifier, with flexible arm is also an invaluable aid.

It always helps to be able to see what you’re doing!

Well thats enough waffling on, for me!

I hope it might help someone in some way!

Edit:

Oops! I meant to add, another invaluable addition would be a cheap multimeter, just for testing continuity of pins from one end to the other. It might save you from a costly mistake!

I interpret this as a Temperature Controlled Soldering Iron. I have used a temp controlled Weller 15/20W iron, which was quite good for small audio stuff, but I don’t own one.

My own iron is a quite old 30W one. It does most things, OK (audio leads, Scalextric cars, guitar wiring & controls - it doesnt care…)

Regarding Solder, Multicore is what I use. I do have some Lead Free, but its a PITA to use. So I used ‘normal’ leaded Multicore, which is still readily available.

Yes, to a (cheap) multimeter to check & test your creations…!!

(better to have a cheap multimeter, than no multimeter… ![]() )

)

Yep!

Temperature controlled - same thing!

Some of the “modern” ones are more “programmable” in that one can save a number of presets, for various jobs, etc.

Further, they often nowadays are becoming soldering “stations” in that they incorporate a soldering iron, a hot air gun and even a hot plate. All working independently and catered for by the preset facilty, etc.

A 3 in 1, if you will…

The hot air is used for surface mount components.

The hot plate is used for entire boards using surface mount components.

There are also 2 in 1 variants, comprising soldering iron and hot air gun, that are becoming increasingly popular with hobbyists even when no surface mount work is required!

The hot air gun is used for heat shrink wrapping! Most come with an attachment specifically for this purpose. Its a metal shield with a curved end which is held behind the heat shrink, in order to protect surrounding components from the heat.

I can thoroughly recommend the Hakko FX-888-D soldering station. I use it effortlessly for everything from cables to brass and white metal locomotive kits. NAC A5 has come to fear me.

![]()

Some of those Chinese Hakko 936 copies are very good indeed. Big Clive on YouTube has done a few reviews. I used to have a Solomon 935 “Ceramic Soldering Iron” and station and it was the best soldering iron I’ve ever owned. Better than any Weller I’ve had. It was £35 about 20 years ago (so not completely bargain basement) and had come down to around £20 on eBay before they disappeared about 10 years ago. One problem is that it’s a complete lottery when getting new tips, so buy a selection and, if you find one you like, stock up as they may not be the same again. The other two problems are that some have the screw cap at the tip end, which can obscure the tip, and the cables are too stiff usually, so they need to be re-wired. Naim would say to use a hairdryer. ![]()

Lead-free solder for hobbyists/beginners is a firm “No” unless you want them to give up their hobby. My final tip would be to use 0.7mm diameter solder. I got this recommendation from the Sound Organisation in about 1983, who got it from Naim Audio. ![]() Boy, has it served me well over the years.

Boy, has it served me well over the years.

I agree, finding quality tips for older irons can be very hit or miss!

I’ve been lucky with cables.

My old soldering station and also my desoldering gun, both have silicon cables.

More recently, I tried out some Aoyue equipment - a hot air station, a twin tipped “tweezer” type iron, and a suction pick-up tool (for tiny SMD work).

All of these also came with silicon cables.

I was a little apprehensive to try them, but their equipment seems to have recieved pretty good reviews and appears to be well made. I only wanted them for very light duties anyway…

Apart from silicon leads, they also all have metal casings and decent transformers inside, too.

I would have said that I tend to prefer the tips that look like they have a ceramic coating (which may not be what it is) but I’ve had a couple of those go in record time recently. And I mean nearly no time at all; perhaps four or five uses and, say, a few hours of being left on unnecessarily. ![]()

I doubt one benefits much from paying more with UK sellers as they probably don’t know what they’re getting either (though that what I do). So I think it’s bulk and China direct. Actually, this would be a great bulk buy for something like DIY Audio where you could have dozens of people test a range of them. There really is no reason whatever to pay £300+ for a soldering station. And if you need 20 of them? Eeek! In fact the prices just make me angry.

I once purchased a “cold soldering” iron which has a tip that looks like a ceramic of some type.

It’s a small battery operated device. It came in a nice shaped hard case.

I was just intrigued as to what it actually was, so I bought one.

Unfortunately, it seems that I wasn’t intrigued enough to actually use it, so no idea how it would work!

Perhaps I’ll try it out, one day!

I cannot see how it could possibly work without the tip being sufficiently hot, so have no idea what the “cold” designation is all about!?

Actually, I’ve made myself intrigued all over again!

Have you ever seen anything like that?

Well, I made myself sufficiently intrigued to finally find out what this thing is!

It’s called “cold heat”

The basic idea is that it requires very little power, so a couple of small batteries is enough.

It is capable of heating up extremely quickly and then cooling down completely extremely quickly, too.

So the solder joint is made by holding the power button in for a few seconds generating almost instant heat, make the joint, then release back to an almost instantly cold tip.

Similar to resistance soldering.

It must be buried somewhere in my workshop, so I might try and find it and give it a go, finally. I’ve only had it for 10 - 15 years!!

All of that is new to me, I’m afraid. Does it work well?

Once upon a time I would be enthused by an idea like this, but nowadays it probably rides under the banner of ‘eco’, ‘green’ or ‘planet-saving’ and their record of doing anything useful or sensible is utterly dismal. The pseudo-clever but actually absurd label of “cold heat” probably tells us which side it’s on. LOL. ![]()

![]()

I have no idea if it works well!

As i said, I bought it probably 15 years ago, maybe more actually, just out of idle curiosity.

I think I may have had a vague idea it might be useful as a portable iron…

Things like the TS100 didnt exist then!

I never did try it out!

It was obviously a complete breakthrough!

After all, that’s how all irons are made nowadays, isn’t it!?

![]()

I have made DIN-DIN cables using Mogami 2534 and 2549, the 2534 was marginally preferable for me (slightly more refined and better detail) however the 2549 does give better bass quality. I preferred both to the Lavender 9No a massive difference, but imo well worth the effort involved.

The biggest advantage from any cable change I’ve ever had came from using Mogami 2497 for the DIN - XLR cables for the NAP300DR; that was an absoute revelation!

Definitely good advice - almost essential I’d say!

I made a 2549 cable to go between a Naim pre amp and a pair of mono 110s.

The amount of detail I was hearing was amazing. However, it sounded unbalanced and fatiguing, so I removed it.

But, since then I replaced the chord mojo with an ndac and bought a better streamer. I’ll be giving it another chance this afternoon. ![]()

I also tried using 2549 from the 272 to the 300DR. I seem to remember getting the same conclusion as you. On the other hand using 2549 from a 272 to a 250DR worked well. The main difference I believe was that for the 250, the return (i.e. 0V) was through the screen whereas with the mono connections to the 300 the cables were configured in psuedo-balanced configuration with the screen connected at the source end only.

The 2497 preserved even more detail, largely kept the dynamics, and yet was also a very well balanced cable. On the other hand, at 8mm diameter, it’s not the easiest to use with DIN plugs and it’s also difficult to strip and solder.

The 2549 is back in the interconnect biscuit tin. ![]()