Ok… it shouldn’t be a massive thread as there is no point showing every wire, resistor being connected. That would be a little tedious for all involved  . The forums, Head Fi and DIYAudio provide a lot of info including the step by step manual which are at DIYAudio dot com plus files for ordering the PCB boards and a full parts list (Google L0rdGwyn Aegis). This is just about my experience as a first time builder and how I got on.

. The forums, Head Fi and DIYAudio provide a lot of info including the step by step manual which are at DIYAudio dot com plus files for ordering the PCB boards and a full parts list (Google L0rdGwyn Aegis). This is just about my experience as a first time builder and how I got on.

So, for a 1st post to get this up to date.

Reading the manual from L0rdGwyn is absolutely essential. As well as instructions it contains vital safety routines that must be followed. We are all responsible for our own safety so you cannot skip it. Read and read it again to understand exactly what you are doing should you decide to give it a go…

This is the gear needed to make life easier building this. Most I feel is essential.

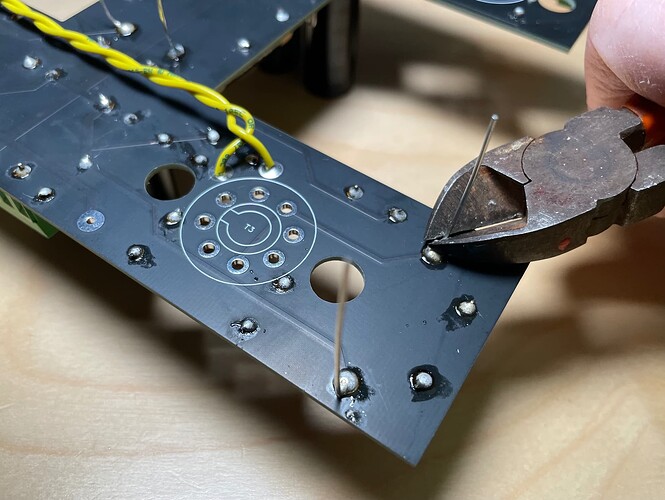

Soldering station, Multimeter, third hand clamping tool, electrician scissors and wire cutters, iFixIt tool set and a hot air blower for cable shrink wrap.

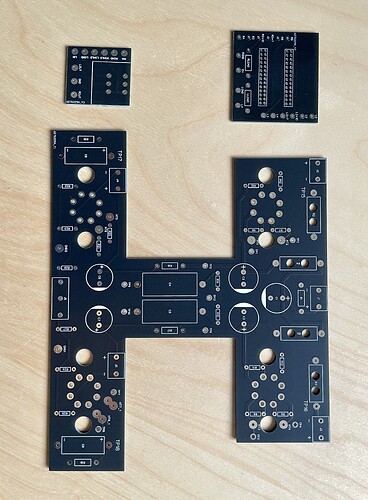

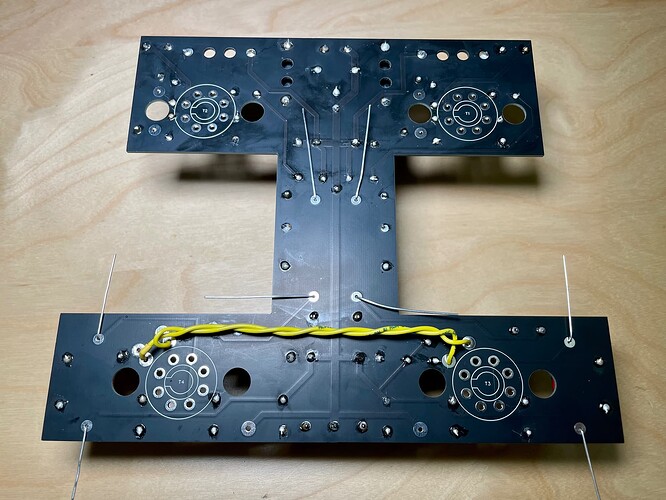

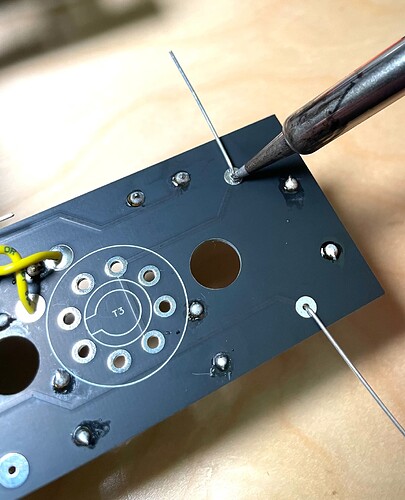

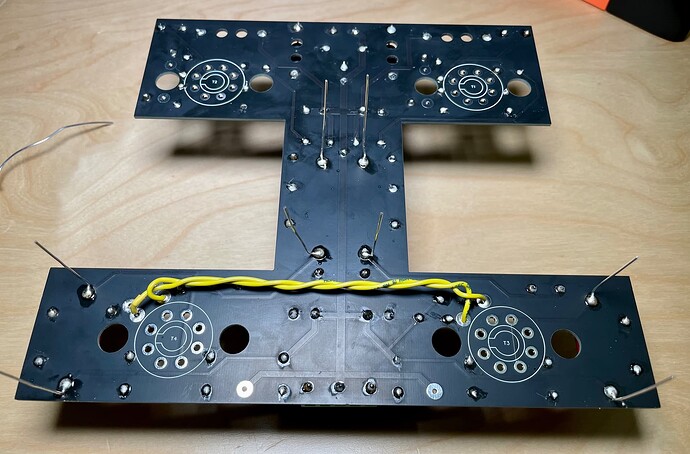

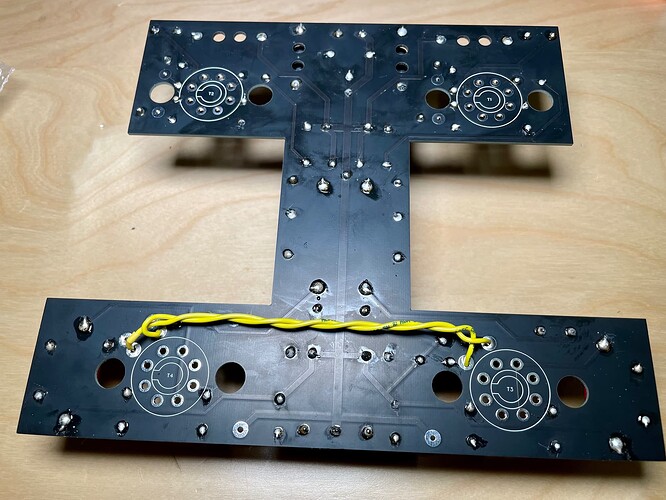

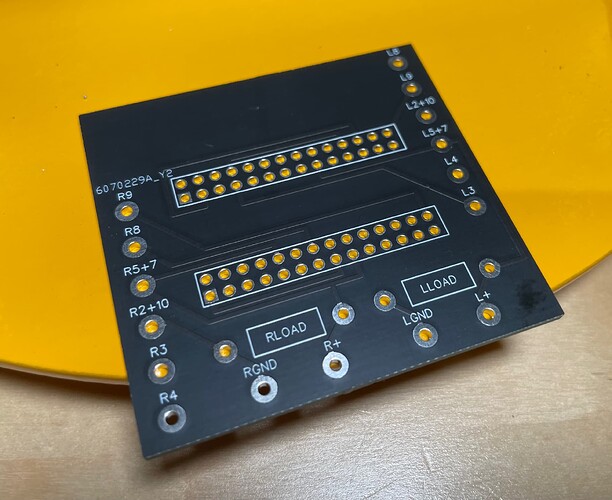

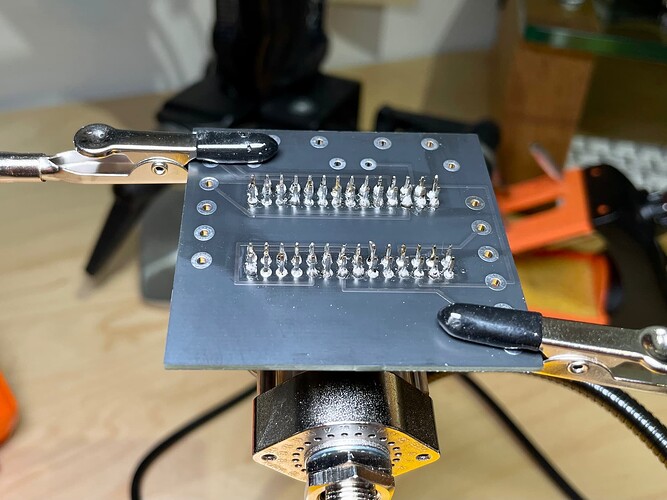

The PCB boards when they arrive look like the photo below. When ordering you have to buy 5 of each but on the forums, there are people selling spares so you can check there first.

So far, parts wise, I’ve received the cabling and resistors etc. Not visually exciting stuff. All 20awg silver coated oxygen free both solid core and stranded.

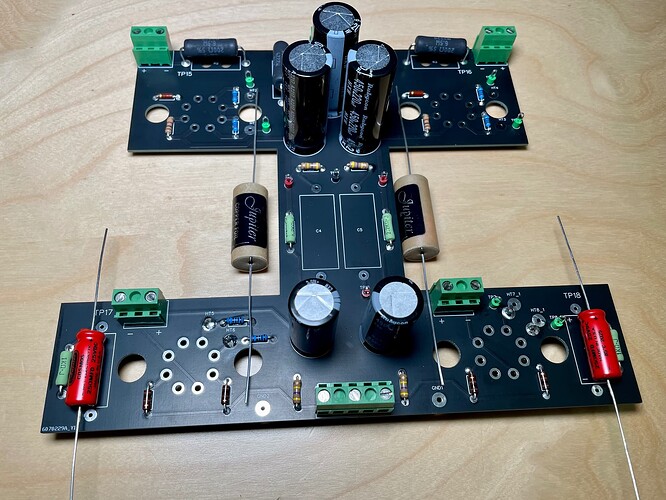

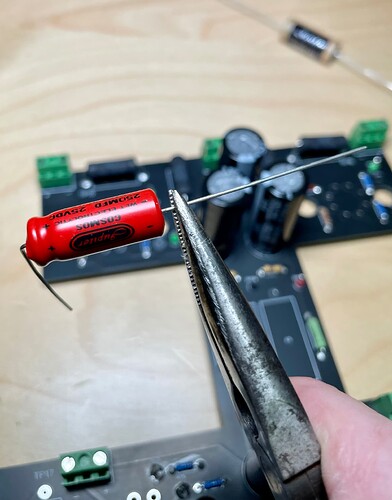

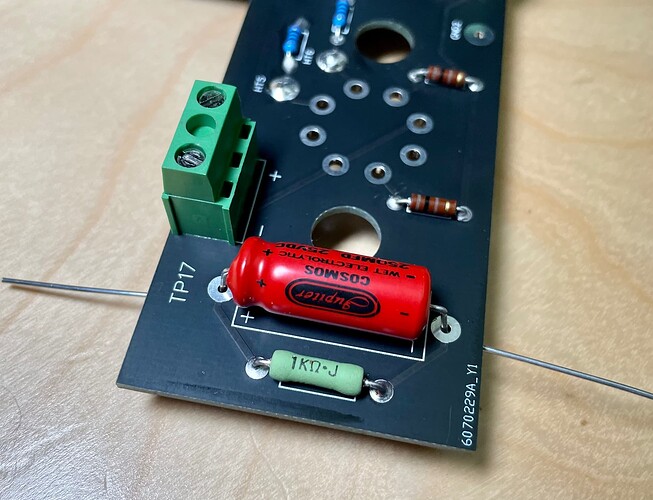

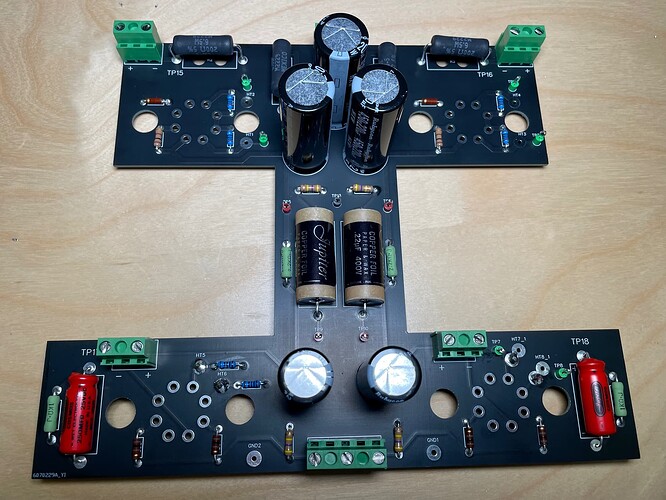

This is where I’m up to with the main board, approx 2hrs work. Just the Jupiter capacitors needed. To be honest, I found it rather relaxing and enjoyable experience. Just took my time and double checked everything. I did practice before hand on a PCB practice kit from Amazon which was cheape and very useful experience!

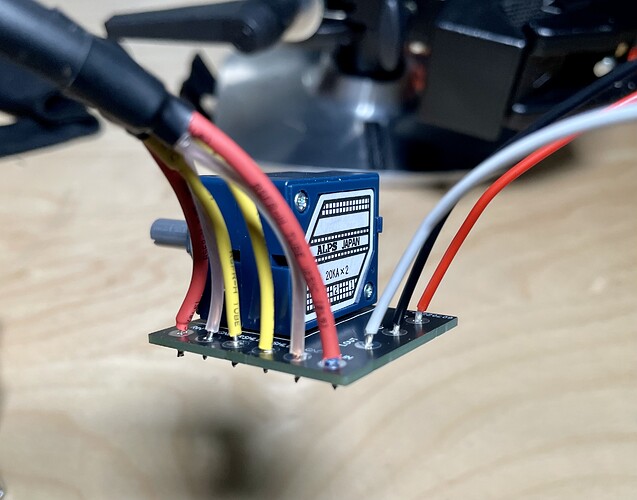

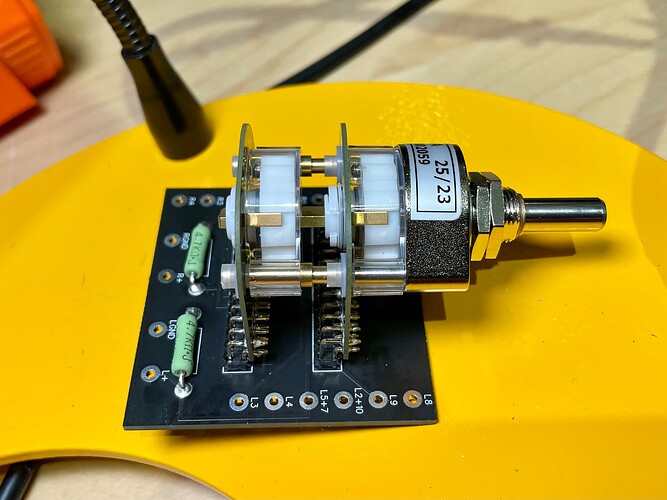

The Alps Blue Velvet volume pot was soldered to its PCB board along with the cables for the RCA sockets and the wires that will connect it to the main PCB board. Extra used so it can be sized perfectly once added to the chassis later.

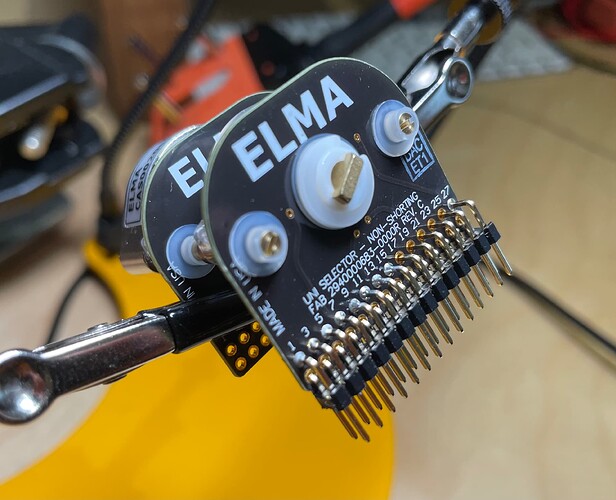

That’s where I’m at for now, waiting on the chassis, 6 Lundahl transformers/Chokes, impedance switch (ELMA) and Jupiter capacitors. The capacitors should arrive next so I can complete the main board.