It would be adding, only. Feets are like shown on the picture above (it is a picture of my CDX2)

Thanks for your reply.

All brass it is ! ![]()

Indeed, a proper concave surface isn’t something trivial to achieve.

The other option would be:

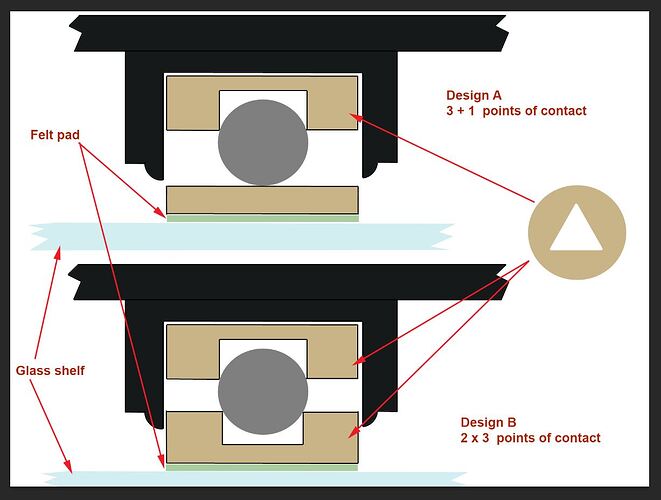

1 - Design A is probably a better option. Easier/cheaper to produce and probably more convenient. We could even have the nitride balls directly in contact with the shelf glass. What would be best?

2 - As for the nitride balls, which diameter would be appropriate considering the electronics weigh around 15kg (25 Kg for the NAP500) ?

3 - Design B has more points of contact, but it might be easier to install.

4 - The big question is how efficient would that design be. Is it worth making it?

I am far for being a specialist however the additional isolation devices work often better alone, under the chassis, not under the stock feet.

The vast majority of systems I have seen have isolation devices under the chassis directly, often 3 devices.

But worth try both choices probably.

But when the isolation devices have not enough height, you have no choice of course.

I wouldn’t suggest any of those.

Use the method I used to put a smooth ‘dent’ into a brass cup. Use the same thing top and bottom.

Don’t forget that if you are planning to use 4 supports you’ll need a very precise way of adjusting them for even pressure. The felt layer will defeat the object of using the brass & silicon nitride as it behaves as a visco-elastic interface.

Weight isn’t an issue, I have a 555PS sat on 3 silicon 6.25mm nitride balls (actually against the brass they’ll take double that force and against bearing steel (or ceramic) they’ll take at least 10 times that loading!

Wouldn’t a “dent” add more contact surface comparing to the triangle 3 points of contact design?

Do you mean something like so:

I wasn’t able to find the pictures/descriptions of your cup design (sectional view). Would you mind posting them again?

Yes this is a potential/probable issue.

I could use the front feet (insert the cups in the feet) and have a thicker third cup placed between the back feet, directly against the chassi. It would then result on an even pressure distribution.

Right. That was to prevent scratching the glass surface. But I suppose that could be avoided with some care when placing the cups.

Any suggestions were I could order quality silicon nitride balls of that size?

As for the efficiency, is it worth the time/money spent? Without an interferometer it is almost impossible to measure. Have you had audible results?

To address your last Q - yes, with Xanthe’s manufactured brass cups and printed surrounds between 10mm glass and with 1/4 inch balls there was a very clear and very enjoyable SQ uplift.

And this was just under my 272. Am going to also do the 555DR and power amp soon so should get much more from these too.

All this is described in detail in the thread above as it worked for me and for Xanthe.

The dents’ diameter need to be larger than the balls’ diameter - again see above thread and suppliers’ names are mentioned there too if they are still there.

BTW, I doubt that doing this inside the feet holes of Naim gear will be the best way to go.

Better to use one glass sheet and Xanthe’s system surely - except I’m not sure how it would apply to your rack?

Hi Xanthe and Jim,

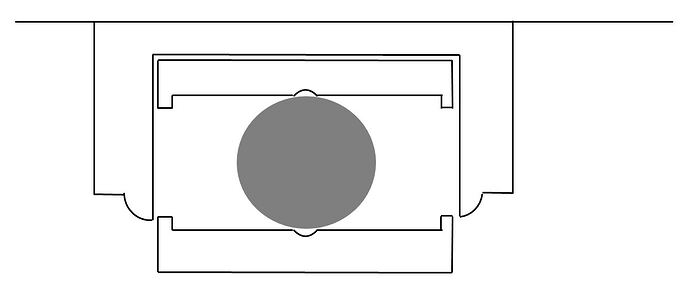

Thanks for the details, I found all the needed info and ended up with this last design:

-

If this is possible I’ll order 6 supplementary feet from Naim.

Each one of them will then be placed at the back as the third foot.

That way the 3 feet supporting the NAC/NAP/ND would be the exact same. -

I’ll use balsa as a replacement for the 3D printed backstop.

-

As for the Si3N4 ball, I suppose grade 5 is enough. Right?

-

@Xanthe why not having the Si3N4 balls directly against the glass shelves?

-

Would it make a significant difference to have 3 points of contact

(the triangle shaped extrusion) -

I chose to tinker the Naim’s feet because of the lack of space between two glass shelves (my rack was custom made to accomodate the Naim boxes, made it myself).

-

@Xanthe your initial design thickness is around 16 mm right?

(cup + nitride ball + glass)

You’re most certainly right. Tinkering Naim’s feet means bypassing its decoupling properties.

The problem is that space between two glass shelves is limited. I designed my rack to accommodate the Naim boxes and their air flow needs.

Not sure that another glass sheet would fit.

3 mm for the brass cup

6,4 mm for the nitride ball

6 mm for the glass sheet

Total: ~1,6 cm

I have 2,3 cm left between the boxes and the upper glass shelf (except for the NAP500 which has 3,8 cm left)

Mine are cheaper!

![]()

It was not my intention to advertise these products. Just to show that they are usually put under the chassis, not under the component feet, for best results.

Your devices work the same.

OK yes, that’s true enough.

And the commercial version probably do have some performance advantage over mine, how much advantage is another question, but it would have to be very substantial to justify their retail prices.

I don’t know which will sound the best. Just wanting to say that Thomas should put them under the chassis, 3 devices in triangular set up . But not under the feet. At least I have done that and it works better…as also in the pictures.

Some have crazy prices. I know.

Yes, that is also how I use them.

I have a question for you.

I bought mini heat sinks ( 37 mn) to put under my Etheregen and Uptone ps, which are running very hot. And probably hotter this summer.

But the Etheregen was designed to run hot .

Do you think it can limit its capabilities if I put heat sink above it?

Because perhaps the clocks are working better at 40/ 50 C and decreasing the heat may not be ideal?

Well, when I fitted one set of the brass cups and inner restrainers unde my 272 that were beautifully and brilliantly and selflessly fabricated by Xanthe, the SQ of the whole system moved up in clarity and solidity and sheer delight by a large and unmistakable notch.

The next morning I decided to try moving my 555dr to my second rack - a Quadraspire one with thin legs and glass shelves that I was using only for switches.

That was a worthwhile experiment which made it clear that glass shelves are not great on a Quadraspire rack. The sq was a little muddied by it, probably because the Psu was wobbling the whole rack and thus vibrating the switches as well as itself.

Anyway, I just put the 555dr back on the oak rack with thicker legs and SQ leapt back up to the lovely place it was at beforehand.

Phew.

The laptop on the switches rack is now funnelling wav files to the 272 via upnp controlled by Kazoo, which is also adding to SQ too.

That means I could try Roon now on the laptop, and see what that sounds like.

Then decide whether to use that laptop permanently, or a NAS, or a NUC or Roon Nucleus, or an Innuous…

Will try Roon tonight if poss…

if you dont like the idea of a laptop and the other options seem a bit pricey, use an apple mac mini. I just set one up, needed a display only to set it up and its ideal for roon server work, i paid £200 for a late 2014 model with i5 and 4gb ram.

Finally got the glass shelves out from under my speakers (replaced by borrowed Living Voice marble slabs).

This further tighened up and cleaned up SQ.

Once again, a heartfelt thank you to Xanthe for everything.

Jim